viscosity classifications

The first and most important task of lubricating oil is to keep moving metal parts separated from each other, thus avoiding metal-to-metal contact, which leads to destructive wear. Even finely machined metal surfaces have a certain roughness.

Contact of these minute metal projections should be minimized; however, some contact always occurs and results in normal wear of the metal surfaces. If contact is not minimized, heat is generated when the metal parts touch. The heat causes local welding andtransfer of metal, which creates scuffing or seizing of the equipment. These actions are called adhesive wear. The oil property that governs the thickness of the separating oil film is the viscosity.

Viscosity

The commonly used kinematic viscosity is defined as a measure of the restrictive flow of a fluid under gravitational force. The “cgs” unit of kinematic viscosity (one centimeter squared per second), is called one stoke (St). The SI unit for kinematic viscosity is one meter squared per second and is equivalent to 10,000 St. Usually, centistokes (cSt) is used (1 cSt = 0.01 St = 1 mm2/s).

The absolute or dynamic viscosity is equal to the kinematic viscosity, multiplied by the density of the fluid. It is usually expressed in centipoise (cP) (1 cP = 0.001 Pa.s).

Viscosity index (VI)

The viscosity of lubricating oil changes with temperature and the rate of change depends on the composition of the oil. Naphthenic base oils change more than paraffinic base oils. Certain synthetic lubricants change much less than paraffinic oils.

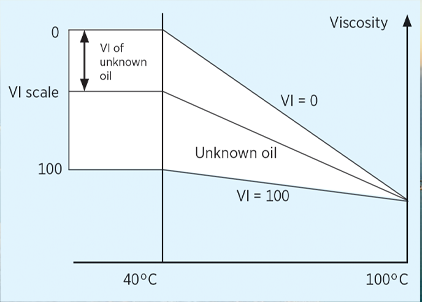

To assess this lubricating oil property, the American Society for Testing and Materials (ASTM) created a method to provide a number called the Viscosity Index (VI). The VI correlates the amount of viscosity change for a given oil, compared to two reference oils having the highest and lowest viscosity indices at the time the VI scale was first introduced (1929). A standard paraffinic oil was given a VI of 100 and a standard naphthenic oil a VI of 0.

Figure 1 shows the relationship between viscosities at 40°C and 100°C. The method has been updated and revised several times to include VI values higher than 100.

Figure 1: Schematic Representation of Viscosity Index

A low VI means a relatively large viscosity change with temperature and a high VI denotes a smaller change of viscosity with temperature. Hence, the VI of an oil is important in applications where an appreciable change in temperature of the lubricating oil could affect the startup or operating characteristics of the equipment. Deck machinery and emergency equipment are examples of typical applications onboard ships.