DOT.FAST® drip oil analysis

onboard and onshore marine engine oil analysis

The market-leading DOT.FAST® test kit empowers vessel operators with fast and accurate marine engine oil analysis.

Analysis of unburned cylinder oil which has passed through the combustion chamber and pistons and liners in the main engine is an effective way to monitor engine wear, minimise corrosion and reduce feed rates.

Drip oil analysis provides the critical insights needed to maintain efficiency and prevent costly failures.

Onboard analysis helps to:

- Minimise consumption by optimising cylinder oil feed rates

- Discover early indications of engine wear

- Minimise build-up of abrasive deposits

- Measure wear onboard with laboratory accuracy

- Maximise time between overhauls

- Perform predictive maintenance and minimise downtime

Onshore analysis helps to:

- Measure total iron content

- Monitor effectiveness of fuel purification

- Identify system oil leakage

- Monitor piston and ring groove wear

- Analyse a specialised range of parameters

DOT.FAST® marine oil analysis helps vessel operators gain the insights needed to enhance performance, reduce costs, and extend equipment life.

What is DOT.FAST® Drip oil analysis?

The sulphur/base number balance

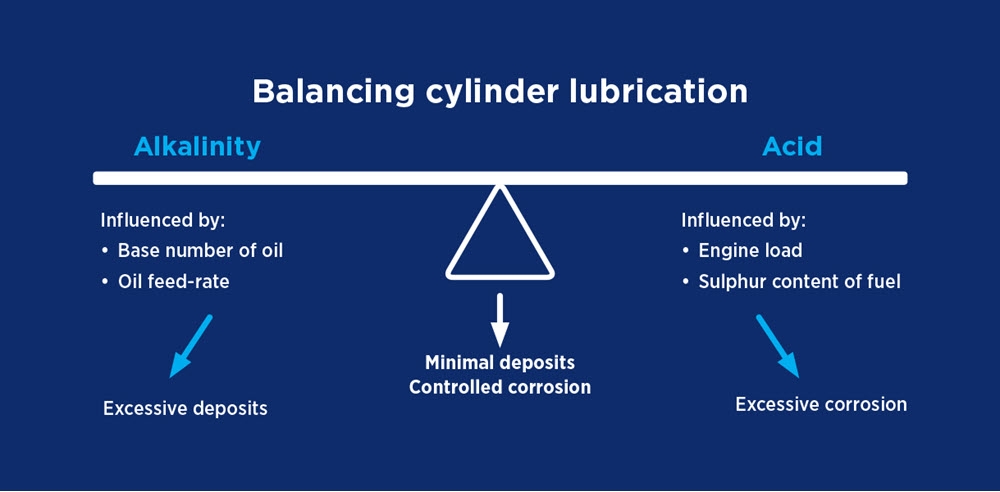

One function of the cylinder oil is to protect the engine from acidic corrosion. This is achieved by the alkalinity of the cylinder oil, defined by its base number (BN) and its feed rate. Too much alkalinity however, will result in the formation of excessive abrasive deposits on the piston crown top lands, ultimately leading to increased liner wear and scuffing.

It is important to maintain the correct sulphur/base number balance. This balance can be achieved by changing to a cylinder oil with an appropriate BN, by adjusting the cylinder oil feed rate or a combination of the two.

The total iron content measured by DOT.FAST® indicates the total corrosive and abrasive wear taking place in the engine, enabling you to make any necessary adjustments.